"TWIN TIPS"

Hints on Tuning and Assembly of the B.S.A. 650 c.c. A10 Engine

Compiled by Eddie Dow

MANY changes have taken place on the A10 engine since its introduction for the Gold Flash in 1950, with a steady improvement ia power output, culminating in the Rocket Gold Star manufactured in 1962 which produced 50 b.h.p. The R.G.S. is already tuned to a high degree and the object of these is notes to help owners of older models to obtain an improved performance. It is not advisable to increase the power output from a very old engine, especially if it is proposed to use the machine for racing purposes, because the possibility of fatigue failure of the more highly stressed components.

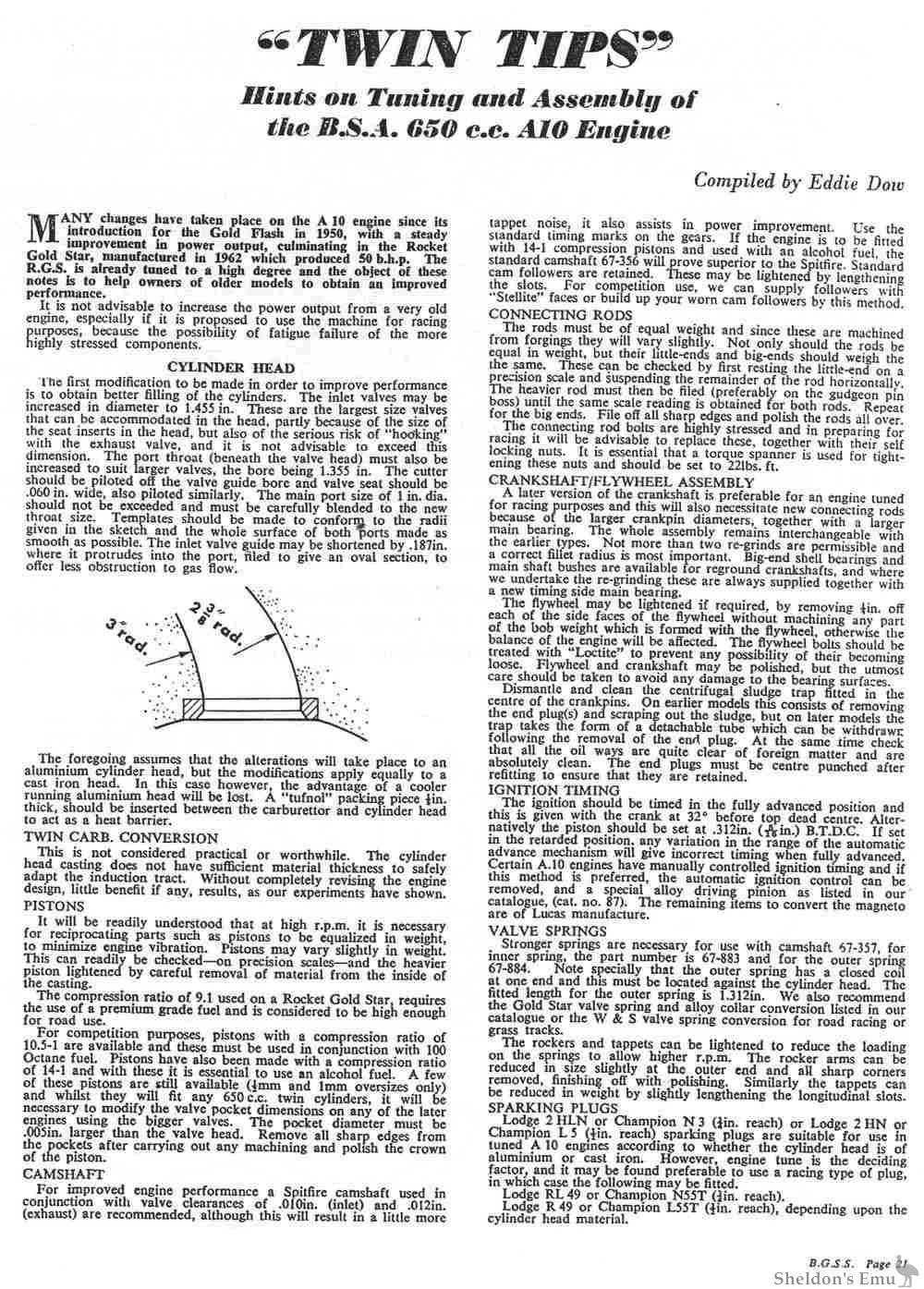

CYLINDER HEAD The first modification to be made in order to improve performance is to obtain better filling of the cylinders. The inlet valves may be incressed in diameter to 1.455 in. These are the largest size valves that can be accommodated in the head, partly because of the size of the seat inserts in the head, but also of the serious risk of "hooking" with the exhaust valve, and it is not advisable to exceed this dimension.

The port throat (beneath the valve head) must also be increased to suit larger valves, the bore beine 1355 in. The cutter should be piloted off the valve guide bore and valve seat should be .060 in. wide, also piloted similarly. The main port size of 1 in. dia. should not be exceeded and must be carefully blended to the new throat size.

Templates should be made to conform to the radii given in the sketch and the whole surface of both ports made as smooth as possible. The inlet valve guide may be shortened by .187in. where it protrudes into the port, riled to give an oval section, to offer less obstruction to gas flow.

The foregoing assumes that the alterations will take place to an

aluminium cylinder head, but the modifications apply equally to a

cast iron head. In this easo however, the advantage of a cooler

running aluminium head will be lost. A "tufnol" packing piece (?)in

thick, should be inserted between the carburettor and cylinder head

to act as a heat barrier.