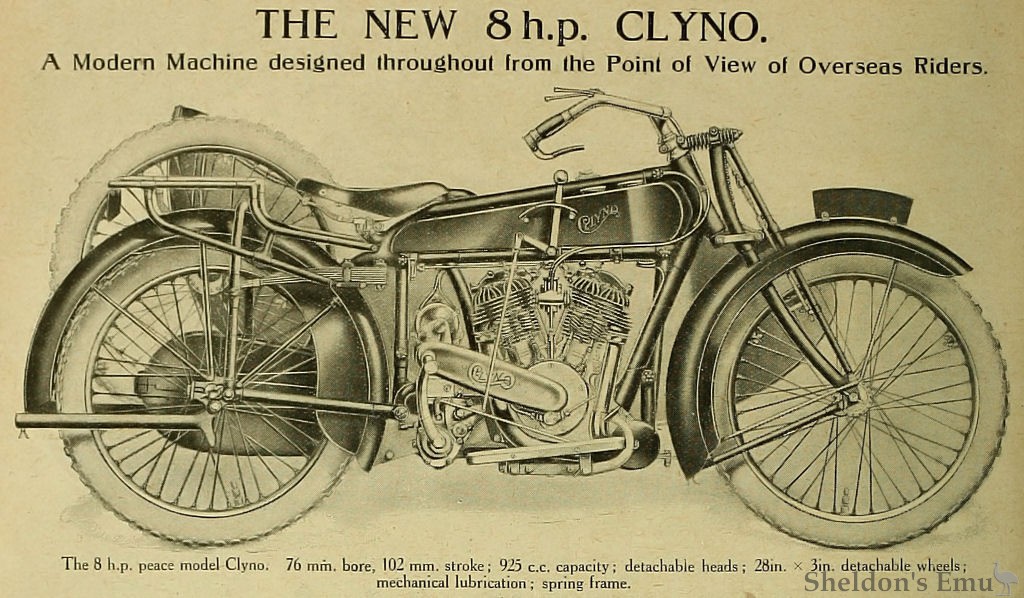

A Modern Machine designed throughout from the Point of View of Overseas Riders.

WE have long urged that British motor cycle manufacturers would benefit by more careful attention to the insistent demands from Overseas for a machine in every way suitable for the special requirements which were only fully covered in the big twin class by certain American machines.

What is required by a large number of Overseas buyers is a large capacity engine, 28x3in. tyres, spring frame, and, coupled with such a specification, British quality in design, material, and workmanship.

The Clyno Engineering Co. in their "peace model" have, it will be seen, appreciated the needs of a vast proportion of the Overseas market, for the new Clyno has been designed throughout, from the point of view of the Colonial, and the result is a machine which sets a new standard of design which will be appreciated just as much by riders at home. The popularity of American machines in this country and Overseas indicates that what is absolutely essential in the Colonies is also desirable in Great Britain ; hence, while the motor cycle designed for this country may not be suitable for South Africa or Australasia, the true Overseas mount is equally good for home or abroad.

The general outlines of the new Clyno, at first sight, appear to follow those of well-known American machines. This, however, probably is due to the high ground clearance (over six inches), the spring frame, and unconventional looking carrier ; because, upon examination, the general design is more British than American.

The Spring Frame.

The frame is of very substantial construction, the makers' experience with their machine gun sidecars being responsible for several special features, notably the exceptionally strong head, which has massive, but by no means ugly, webs on each side and at the rear of the casting. Both top tubes slope towards the rear, terminating in a single member embodying the carriers for the rear springs, and a lug for a vertical tube, which takes the place of the more conventional "seat" tube. The foot of this tube is the pivoting point of the rear wheel frame, between which and the engine the gear box is carried. Forward of the latter unit is another " down " tube, the only bent tube in the principal frame structure. This supports the engine on one side and the gear box bracket on the other. The four sidecar lugs are integral with the frame, the two rear members being on the vertical rear tube, while, to meet the stresses caused by the sidecar, the front down-tube is l ½in. in diameter, and strengthened internally by high tensile steel tie-bars.

Comparatively short springs with seven leaves are hinged at their rear ends on the sides of a loop member over the wheel, which in turn is pivoted at the ends of the chain stays. The bearings of the loop are of good size, while at the frame end the bearings carrying the stays are calculated to prevent any lateral play. All moving parts are equipped with grease cups. The carrier is on the spring portion of the machine, and is of tubular construction.

Mudguards and Wheels.

Deep valances are fitted to the 5in. rear mudguard, which is well stayed, as is the wide front guard.

Quickly detachable and interchangeable 28in. x 3in. wheels with voiturette rims are fitted, and these have solid steel hubs and large adjustable ball bearings.

An 8in. internal expanding brake is fitted on the driving mechanism at the rear wheel, and is operated by a pedal on the left side of the machine. The shoes are faced with Ferodo, and therefore renewable. The front brake is of the conventional type, i.e., fibre pads in shoes working upon the rim of the wheel and operated by lever on the handle-bar. The latter is of good width, gives a comfortable riding position, and in shape may be described as a step between the conventional upturned bar and that which is known as "semi-T.T."

Front and back stands and Brampton type forks complete the main elements of the frame.

The Long-stroke Engine.

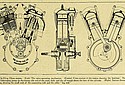

(Left) The valve-operating mechanism. (Centre) Cross-section of the engine showing the bearings. Note the small lubricating pump on the timing side end ot the main shaft, and the oil trough about the base of the cylinder. (Right) Section through the jngine, showing the small ends of the connecting rods and the roller "big end."

We may say that it is a long time since we were so favourably impressed by a motor cycle engine, both in the points of design and performance. The bore and stroke are 76 and 102 mm. respectively, which give a total capacity of 925.5 c.c. The cylinders are set at 42°, which we think is somewhat unique in British machines, the most general setting being 50°. The cylinder dimensions show that the engine is of the long stroke type ; in fact, the stroke, in proportion to the bore, is longer than that of any British twin motor cycle engine hitherto produced, the ratio being nearly 4 to 3.

Important features are the detachable heads and the methods adopted to hold them in position. On two sides of each cylinder there is a swivelling bolt extending from the crank case to above the cylinder heads where they are linked by bridge members, which bear upon the centre of the cylinder heads. The part in contact is concave on the cylinder and convex on the bridge piece, which makes the latter more or less self-centring.

To detach a cylinder head it is only necessary to remove one nut, slacken the other, and swing the bridge piece clear. The head removed, together with the valve chests and valves, the cylinder barrels may then be withdrawn without further use of tools.

The cylinder barrel is spigoted into the head, and a gastight joint made by the usual copper and asbestos ring. The top fin on the cylinder barrel is " dished " to receive the rim of the socket portion of the joint.

Thirteen fins encircle the cylinder barrel and are joined together at four points of the circumference by what may be described as vertical webs. The head portion has "upright fins" across it, while the valve chambers have fins arranged approximately radially.

The pistons have flat tops, and are of cast iron, with four webs. Three rings are fitted at the top, and below them for nearly half its total length the piston is recessed, and has a narrow skirt with a strengthening rib about its bottom edge. In the waist of the piston are a number of holes, introduced to lighten it. Extra long bosses are provided for the gudgeon which works in them. The gudgeon pin is fixed in the small end by means of a cross bolt, the connecting rod having a saw cut from the lower part of the small end bore extending into the I section rod, to allow the small end to grip the gudgeon pin when the bolt is tightened up. Thus, it is evident that, instead of the connecting rod working upon a fixed gudgeon pin, the latter moves in the bosses in the piston. By these means there is approximately a hundred per cent gain in bearing surface over the more conventional bushed small end.

The "Big Ends."

As will be seen from the drawings, one connecting rod is forked, which is another departure from previous Clyno practice, the 5-6 h.p. model having side-by-side connecting rods. The big ends are fitted with roller bearings, each having two rows of rollers in bronze cages. The plain connecting rod has two rows side-by-side, while the forked rod has a row on each side of the other pair. The cages are of one type, and the pair on one side faces the pair on the other, having a hardened and ground steel ring between them. The big ends are lined with renewable hardened and ground steel rings.

Crank Pin.

The method of fixing the crank pin is novel. Although it has been in use some time on war-time Clynos, the design is not generally known by the motor cycling public. The crank pin is hollow, and has tapered ends, which fit in tapered holes in the flywheels. Through the centre of the pin there is a shouldered bolt, with a large head on one side and a shouldered nut on the other. By tightening the latter, the crank pin is pressed firmly into the flywheels. Each end of the bolt has a locking device, which will be seen in the third drawing of the engine.

Main Bearings.

Long plain phosphor bronze bearings support the main shafts, the adoption of which, no doubt, contributes to the silence of the engine, which we inspected after many thousands of miles of running. Page 8l6

A single cam wheel, which is supported in bearings at both ends of its shaft, operates the valves on both cylinders through three pairs of rockers. The exli.Tust rockers, having the greatest amount of work to do (i.e., to open the exhaust valves against the pressure of the expanding gas in the cylinders), are fitted with rollers. Two pairs of rockers are used to operate the inlet tappets, the arrangement of which will be clear from the drawings.

An extremely neat exhaust valve-lifting mechanism is embodied within the timing gear case. This is in the form of a stirrup which, upon being raised by means of a Bowden wire, takes both exhaust rockers out of action. Means of adjustment are provided by two knurled collars.

The tappets, which are adjustable, are equipped with light springs to keep them in contact with the valve stems, while double springs are fitted to the valves, which are of ample diameter.

It will be seen from the drawings that the induction pipe is very short, and is fixed by screwed collars, which compress washers of asbestos, and so obviate all chance of air leaks at this important point.

Exceptionally large exhaust exits are provided, with l ½ in. exhaust pipes carrying the spent gases in easy curves to a long 4 ½in. barrel silencer.

Lubrication.

At their lower ends the cylinders extend deeply into the crank case, the space between them and the crank case walls being utilised as an oil trough into which fresh oil is pumped by a small eccentric pump on the engine-shaft. This pump draws its supply of oil from a drip feed on the tank. In the walls of the cylinder barrels are a number of holes through which the oil overflows and so lubricates the pistons. In addition to these holes, there is a pipe in the trough through which oil flows directly to the timing side main bearing.

On the driving side the oil which drips down the inside of the crank case is collected in a trough just above the bearing, to which it is fed by a large oilway.

No special means are adopted to lubricate the crank pin and gudgeon pins, which secure their share of lubricant by splash in the usual way. In addition to the mechanical lubrication system, the machine has an auxiliary hand pump with a two-way tap, by which the driver may give either engine or gear box a charge if and when required.

Shock Absorbing Device.

In our previous reference to the new Clyno on the road we mentioned the extremely smooth running of the machine. There is no doubt that the shock absorber largely contributes to this. The device consists of a sprocket, free on the engine-shaft, and having four cams on its outer side. These bear upon four spring-loaded plungers carried in a member which is fixed to the engine-shaft. Thus, the impulse of the engine does not impart a shock upon the transmission. In addition to the spring pressure, there is the frictional contact between the sprocket and the member against which it is held by the plungers.

The Gear Unit.

We are not permitted to give full details of the new three-speed gear box. It is interesting to note, however, that while the gears are the same size as the gear unit of the 5-6 h.p. model, the complete box is 6 lb. less in weight. The layshaft is of the built-up type, while the gear wheels are |in. and ^in. wide. All gears are in mesh, and engagement is obtained by dog clutches of the internal tooth type. The kick-starter is entirely enclosed.

The clutch is of the multiple plate type, with cork inserts, and fitted with roller bearings. It embodies a single adjusting spring, and is operated by the right foot. On the top of the gear box is carried the magneto or mag-dynamo, whichever may be fitted. This is driven by a chain enclosed in an aluminium case as hitherto.

At every point it has been remembered that it is necessary to guard against sand clogging the working parts, which are usually exposed. For example, the quick thread operating the clutch, although only outside the case for less than ¼in., is protected by a sleeve.

Built-up Chain Cases.

The 5/8in. x 3/8in. chains are entirely enclosed in strong metal cases, reinforced and built up on castings, and are as solid as the aluminium type previously fitted. The method of construction has been thoroughly tried out on the sidecar machine guns supplied to the Government. The mode of fixing is simple, and renders their removal an easy matter.

Accessibility at every point is a strong feature of the design. The footboards and pedals are built up as a complete unit, which may be removed by withdrawal of two bolts. The clutch is rendered accessible by detaching two screws on the domed cap and two nuts on the top of the case.

Space does not permit of a detailed description of the sidecar, which we leave for a later date. It suffices to say that it is a carefully thought out design, embodying a wheel sprung by quarter-elliptic leaf suspension.

The body is roomy, and is suspended on large C springs.

Altogether the new Clyno impresses us as a thoroughly sound proposition, and one which will remove much of the complaint against the British motor industry, that Empire trade is not regarded seriously.

The Motor Cycle, February 20th, 1919. Pages 184-186.